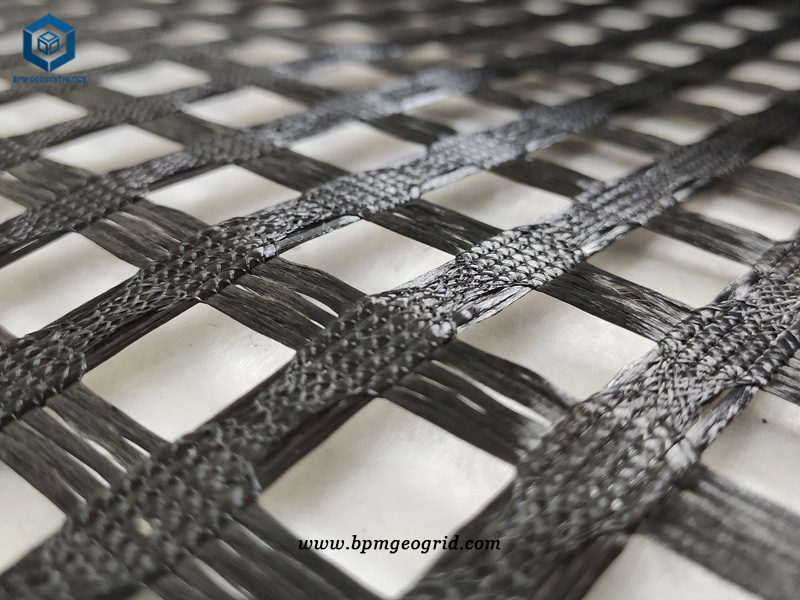

Warp knitting polyester geogrid fabric, also known as warp knitted geogrid, is made of high tenacity, high oriented polyester filament fiber using by the complex knitting process. The warp fiber yarns in the warp-knitted polyester geogrid are directly wound and cross-bundled with the high-strength fiber filaments in the same dimension to form a strong bonding point, which has excellent mechanical properties and long-term strength stability. Warp knitted polyester geogrid has the characteristics of high tensile strength, small ductility, strong reinforcement, high tear resistance, balanced vertical and horizontal strength, wear resistance, corrosion resistance, and light weight, which can effectively lock soil or Crushed stones greatly enhance the shear resistance and overall stability of the soil. Warp-knitted polyester geogrid is widely used in road, railway, municipal and other road soft soil foundation treatment and the reinforcement and protection of roadbed, dam and other projects.

Case Analysis

- Location: Australia

- Product: Warp knitted polyester geogrid

- Project: Building Foundation Reinforcement

- By partnering with customers to deliver advanced solutions, BPM develops and produces materials that improve performance, reduce costs and deliver measurable results.

Project

To create a stable platform when construction began, contractors placed sacrificial stones on the loose, exposed, over-excavated soil.

Another solution was to lay a layer of BETW600-50 high-strength woven geotextile over a soft subgrade, using fewer stones to stabilize the subgrade for construction, as in the case of a geothermal power plant built in Brawley, California as in the case study. The bottom geogrid lift is constructed using a biaxial geogrid. Use the scraper and dozer to place the first 8-inch compaction hoist of the mixed soil mix to spread the material.

Challenge

Soil stabilization, controlled differential settlement and resistance to seismic liquefaction were required to support a 4-storey timber-framed feature hotel in Huondon, North Queensland. The project site is located on cultivated land above alluvial layers with a shallow water table. Geosynthetics made of polyester fibers are used to carry static building loads on extended foundations, reduce settlement and provide resistance to liquefaction during seismic events.

Solution

Biaxial strength geogrids are used to provide soil stabilization under the building footprint and extend beyond 10 feet. First, the design called for the removal of the upper 7 feet of native silt and clay. A stable polyester geogrid farbic reinforcement platform is designed with natural soil mixed with imported sand and gravel, and 5 layers of BPM biaxial geogrid are placed and compacted. The stronger biaxial geogrid was used on the bottom layer for roadbed stability, allowing the lighter biaxial polyester geogrid fabric to be used on the upper layer. BPM geogrids consist of woven polyester fibers in a PVC coating. Unlike polypropylene-based biaxial geogrids, polyester provides high strength at low strain, making BPM polyester biaxial geogrids ideal for supporting long-term static building loads.

Large rubber tire scrapers run directly on the BPM geogrid. The PVC coating on the BPM geogrid provides excellent resistance to building damage. The contractor completed the geogrid reinforcement platform by placing 4 layers of biaxial geogrid between 8-inch compaction fill lifts. A stone base was placed above the geogrid-reinforced platform to provide an unobstructed area to install utilities.

Project Use Product Specifications

- Product: Warp knitted polyester geogrid

- Specification: 110 kN/m and 120 kN/m

- Roll Size: 3.95m×50m

- Quantity: 32000 m2

Benefit

The warp-knitted polyester geogrid fabric uses polyester polyester fiber as raw material. With warp knitting and directional structure, the warp and weft yarns on the fabric do not bend each other, and the intersection points are combined with high-strength fiber filaments to form a firm joint point and give full play to its mechanical properties. The warp knitted polyester grid has the characteristics of high tensile strength, small tensile force, high tear strength, and small difference between longitudinal and transverse strengths. Anti-ultraviolet aging, wear resistance, corrosion resistance, light weight, strong locking force with soil or gravel, by strengthening soil shearing and reinforcement, it plays an important role in improving soil integrity and bearing capacity.

It has the characteristics of high tensile strength, low elongation, corrosion resistance, aging resistance, strong substrate bite force, light weight, and strong drainage capacity. The warp-knitted polyester geogrid is used for road, railway, municipal road and other road soft soil subgrade reinforcement, which can improve the subgrade strength and delay the reflection crack of the road surface. The reinforcement and isolation of embankments and river embankments in warp-knitted geogrid water conservancy projects strengthens the foundation of soft soil foundation, enhances its protection ability, and improves the bearing capacity and stability of the foundation.

Summary

Using the economy of geosynthetics made of polyester fibers, a 4-storey hotel was built on a soft subgrade. The design does not require expensive piles or stone columns to support the building. The design uses native soil mixed with sand and gravel and the friction provided by the BPM biaxial geogrid to provide soil stabilization, limit differential settlement and resist seismic liquefaction.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.