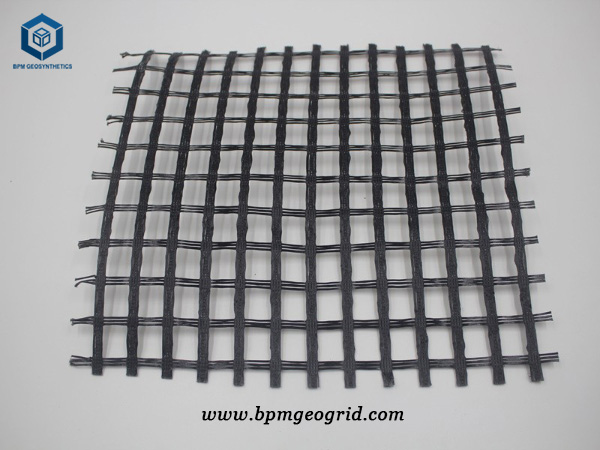

Warp knitted polyester geogrid driveway is the kind of biaxial geogrid product which is widely used to reinforce soils and similar materials in the road or highway construction projects. Geogrids are generally divided into steel-plastic grids, fiberglass geogrids, uniaxial or biaxial geogrid, warp knitted polyester geogrid, etc. Warp knitted polyester geogrid driveway is specially engineered geotechnical material that should be meet the construction demand according to the engineering requirements. Different geogrids have different prices. Generally, warp knitted polyester geogrid driveway is used to reinforce and strengthen road or highway sub base soil. However, it is still necessary to decide which type of warp is to be used according to the construction unit and the owner according to the geographical environment and cost of the project site. The most important point is that the quality of the warp knitted polyester geogrid driveway product determines the geogrid product price.

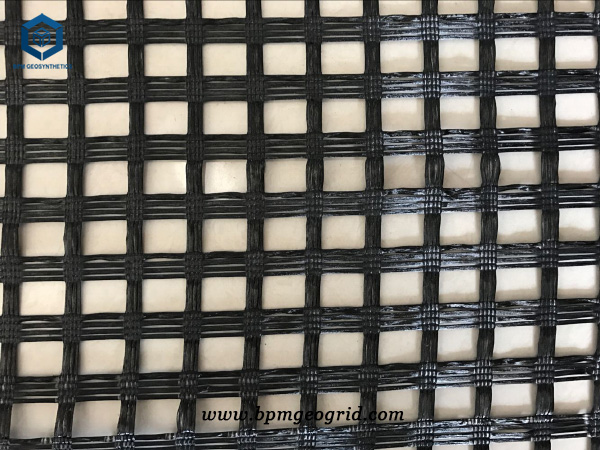

The warp knitted polyester geogrid produced by BPM Geosynthetics uses high quality polyester high strength synthetic fiber as raw material. The warp-knitted bidirectional structure is adopted, and the warp and weft yarns in the fabric have no bending state with each other. The crossing points are bound and combined with high-strength fiber filaments to form a firm joint point and fully exert its mechanical properties. The warp knitted polyester geogrid produced by BPM Geosynthetics has the normal specifications of 25KN-120KN, the width can be 6m, and the length is 50m. Special specifications can be customized as per your demand. The price of warp knitted polyester geogrids ranges from 0.7 dollars to 8 dollars, and the the warp knitted polyester geogrid can be sold in accordance with the ordered specifications and raw materials.

The warp knitted geogrid produced by BPM Geosynthetics has the typical characteristics of finest quality, high tensile strength, small extension force, high tear strength, small difference in vertical and horizontal strength, UV aging resistance, wear resistance, corrosion resistance, light weight and competitive factory price. The warp knitted geogrid driveway has a strong locking force, which has a significant effect on enhancing the shear strength of the soil and strengthening the integrity and load capacity of the soil. The warp knitted polyester geogrid driveway has the following applications.

- Various high-grade roads and railways to reinforce and isolate different soil-based materials for soft subgrade reinforcement.

- River banks and embankment slopes.

- Strengthen and stabilize various foundations and walls.

- Road deck strengthening and slope protection.

BPM clients wanted to purchase GSJ80-80 warp-knitted polyester biaxial geogrid for roadbed reinforcement project. BPM clients came to our factory, took a comprehensive view of the geogrid production equipment, raw materials, production process, and finished products of the warp-knitted polyester geogrid driveway. The polyester biaxial geogrid were professionally tested. BPM clients were very satisfied with our geogrid products quality and our professional production processeds. We held talks in the factory meeting room. The inspection team recognized our company very well and signed a purchase and sales contract of 120,000 square meters on site.

Specifications of Warp Knitted Polyester Geogrid Driveway in Philippines

- Polyester Geogrid Specifications – GSJ80-80

- Each piece size – 6 × 50m

- Total Quantity – 120,000 Square meters

Warp Knitted Polyester Geogrid Installation Guides

- The construction site is required to be compacted and leveled, to be horizontal, and to remove spiked protrusions.

- Polyester geogrid driveway should be installed on a flat and compact site, the main force direction (longitudinal) of the installed grid should be perpendicular to the axis of the embankment, and the laying should be flat, without wrinkles, and tightened as much as possible. It is fixed with pins and earth and stone weight. The laid polyester geogrid driveway is mainly loaded in the direction of force and has no joints. The connection between the polyester geogrid driveway and the polyester geogrid driveway can be manually tied and overlapped, and the overlap width is not less than 10cm. If the polyester geogrid driveway is set in more than two layers, the layers should be staggered. After laying a large area, adjust its straightness as a whole. After filling a layer of soil, before rolling, the polyester geogrid driveway should be tightened again manually or with a machine, the strength should be uniform, so that the polyester biaxial geogrid is in a straight state in the soil.

- Paving and compaction of the filler. After the polyester biaxial geogrid is laid and positioned, it should be filled with soil in time. The exposed time must not exceed 48 hours, and the flowing operation method of laying and backfilling can also be adopted. First spread the filler at both ends, fix the polyester biaxial geogrid, and then advance to the middle. The rolling sequence is first two sides and then the middle. When rolling, the roller cannot directly contact the reinforcement. The uncompacted reinforced polyester biaxial geogrid body is generally not Allow the vehicle to run on top to avoid dislocation of the reinforcement, and the compactness of the lamination is 20-30cm.

About BPM

The Best Project Materials Co., Ltd. has been focusing on the research and development, production and wholesale of geosynthetic products such as geomembrane, geotextile and geogrid since its establishment in 2007. BPM Geosynthetics has become a leading manufacturer of geotechnical materials and its products are exported to 36 countries and regions. BPM geosynthetic products are widely used in water conservancy, environmental protection, municipal engineering, aquaculture, sewage treatment, tailings anti-seepage, biogas environmental protection, landfill sites, garden landscape and water conservancy projects, etc. Welcome to contact us for cooperation!