There are main four types of geogrid available on the market which are widely used to reinforce or stabilize soils and other materials for subgrade improvement, pavement base reinforcement, or retaining walls, etc. Geogrids is a major geosynthetic material with unique properties and efficacy compared to other geosynthetics. Geogrids are often used as reinforcements for reinforced earth structures or as composite materials. Due to the abilities of strength in tension and heavy load distribution across large areas, geogrids are applied to hold or capture the aggregates together to offer chemical, mechanical durability in any environment. BPM manufactures and supplies four types of geogrid such as plastic geogrid, steel geogrid, fiberglass geogrid and glass fiber geogrid.

Four Types of Geogrid

- Plastic geogrid

- Steel geogrid

- Fiberglass geogrid

- Glass fiber geogrid

(1) Plastic geogrid

Plastic geogrid is the most widely used tyoes of geogrid which is made from high density polyethylene. BPM brand plastic geogrid meets the ISO 9001 standard. Plastic geogrid is characterized by good corrosion resistance and high junction efficiency. Divided by shapes, the plastic geogrid mainly has three types such as biaxial plastic geogrid, uniaxial plastic geogrid and triaxial plastic geogrid. Plastic geogrid can effectively prevent soil erosion, ground subsidence and water pollution. Compared with traditional materials, this types of geogrid is extensively used to reinforce soil structure and prevent ground rupture for municipal engineering and geotechnical projects. Plastic geogrid can be applied in many places, such as stadiums, parking lots, airports, railways, highways and piers. plastic geogrid is more durable.

Features of Plastic Geogird

- High strength

- Anti-corrosion

- Erosion control

- Good aperture stability

- Good bearing capacity

- High junction efficiency

- Durable; long service life

Applications of Plastic Geogird

- Widely applied in railway and highway construction.

- Widely used in the reinforcement of retaining wall, embankment, roadbed and dam, etc.

- Extensively used to prevent soil erosion, ground subsidence and water pollution.

(1.1) Biaxial Geogrid

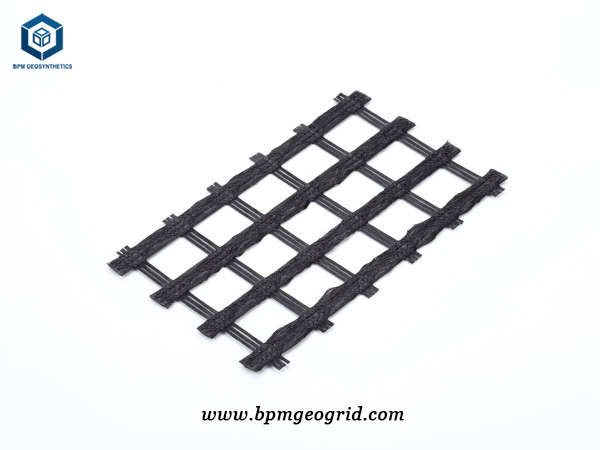

Biaxial geogrid is one types of geogrid which can be made from high polymer. Biaxial geogrid has high strength in both longitudinal and transverse direction. It is made through the process of extruding, sheet forming, punching and stretching. Biaxial geogrid has good bearing capacity. It can enhance soil structure and prevent soil erosion. This product is often used to prevent the road from reflective and fatigue cracking. Biaxial geogrid can effectively improve the long term durability of subgrade and greatly reduces road maintenance costs.

Biaxial geogrid has good resistance to long term degradation. It is suitable for various applications, such as embankment reinforcement, wall reinforcement, soil stabilization, slope protection and other permanent load bearing foundation reinforcement. BPM biaxial geogrid has the characteristics of good bearing capacity, stable aperture size, high elastic modulus, small deformation, high junction efficiency, quick installation and low maintenance costs. The biaxial geogrid is the ideal types of geogrid used in the reinforcement of parking lots, haul roads, landfills and airport runways. It is used to enhance the bearing capacity of railways and highways, to reinforce the durability of buildings and constructions, to prevent landslide and ground subsidence.

(1.2) Uniaxial geogrid

Uniaxial geogrid is a another types of geogrid which can be made from high polymer. This uniaxial geogrid is designed for roadbed and pavement improvement. The uniaxial geogrid is characterized by a one-way stretch structure. This unidirectional structure forms a compact interlock system. Uniaxial geogrid has good flexural stiffness and high strength. It can effectively reinforce soil structure and prevent soil from displacement. Uniaxial geogrid largely increases the durability of subgrade structure and prolongs the road life. Uniaxial geogrid can greatly reduces aggregate fill thickness. It provides a cost-effective solution for civil engineering and geotechnical projects.

Uniaxial geogrid has the characteristics of high tensile strength, small deformation, good creep resistance, good installation damage resistance, good long term degradation resistance, etc. Uniaxial geogrid is suitable for various soil types and climate conditions. It performs well in preventing slope and road from landslide and subsidence. Uniaxial geogrid is widely applied roadbed stabilization, pavement improvement, retaining wall and bridge abutment reinforcement.

(2) Steel Plastic Geogrid

The steel-plastic geogrid is made of high-strength steel wire (or other fiber), specially treated, with polyethylene (PE), and other additives, and it is extruded into a composite high-strength tensile strip with rough pressure on the surface. The pattern is a high-strength reinforced geotechnical belt. The single belt is formed by longitudinal or transverse arranging or clamping, and is welded by a fusion welding technique with special strengthening bonding to form a reinforced geogrid.

Features of steel Plastic Geogrid

- High strength, small deformation.

- Good dimensional stability.

- Strong bearing capacity.

- High friction coefficient.

- Low elongation rate at break.

Applications of steel Plastic Geogrid

- Widely applied in many areas: roads, railways, highways, bridge abutment, approach roads, docks, dams, retaining wall and so on.

- Extensively used in the base reinforcement and soil stabilization.

- Commonly used in the construction of parking lots, airport runways, embankments reservoirs and dams.

(3) Glass fiber geogrid

The glass fiber geogrid is a geo-composite material made of glass fiber and made of a certain weaving process. It is a geocomposite material which is protected by glass fiber and improves the overall performance. The main component of glass fiber is: silicon oxide, which is an inorganic material. Its physical and chemical properties are extremely stable, and it has high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability. Good property; the mesh structure makes the aggregate interlock and limit; improve the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has two-fold composite performance, which greatly improves the wear resistance and shearing capacity of the geogrid.

Sometimes combined with self-adhesive pressure-sensitive adhesive and surface asphalt impregnation, the grid and asphalt pavement are tightly integrated into one. Due to the increased interlocking force of the earth and stone in the geogrid grid, the friction coefficient between them increases significantly (up to 08 to 10), and the pull-out force of the geogrid embedded in the soil is due to the gap between the grid and the soil. The frictional bite force is stronger and significantly increased, so it is a good reinforcement material. At the same time, the geogrid is a kind of plastic flat net material with light weight and certain flexibility. It is easy to cut and connect on site, and can also overlap and overlap. It is easy to construct and does not require special construction machinery and professional technicians.

Features of Glass Fiber Geogrid

- Good wear and creep resistance.

- Good fatigue cracking resistance.

- High tensile strength.

- Small deformation.

- Excellent thermal stability.

Applications of Glass Fiber Geogrid

The glass fiber geogrid is widely applied in asphalt pavement reinforcement, soil stabilization and embankment reinforcement. It also can be used as secondary enhanced geogrid. The glass fiber geogrid is commonly used in subways, railways and highways construction. in the reinforcement of soft soil, segmental retaining walls, slopes and subgrade.

(4) Polyester Warp Knitted Geogrid

The polyester fiber warp-knitted geogrid is made of high-strength polyester fiber. The warp-knitted oriented structure, the warp and weft yarns in the fabric are not bent with each other, and the intersections are combined with high-strength fiber filaments to form a firm joint point, giving full play to its mechanical properties, high-strength polyester fiber warp-knitted geogrid The grid has high tensile strength, small elongation force, high tear strength, small difference in longitudinal and transverse strength, resistance to ultraviolet aging, abrasion resistance, corrosion resistance, light weight, strong interlocking force with soil or gravel, and reinforcement of soil. Shearing and reinforcing improve the integrity and load of the soil and have a significant effect.

About BPM

As the leading geogird and geosynthetics manufacturer and exporter, The Best Project Material Co., Ltd (BPM Geosynthetics) has been dedicated to supplying one stop geogrid and geosynthetic solutions to worldwide customers since its foundation in 2007. BPM has more 120 professional staffs and 16,000 square meters manufacturing factory equipped with state-of-the-art production lines and testing equipment.

Product innovation, customer satisfaction and quality assurance are our long term commitment to our partners. Our main innovative, high quality geogrid products include include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. All BPM brand geosynthetic products had been certificated by the ISO9001, OHSAS18001 Certificate, ISO14001, Soncap, SASO and BV certificates and passed the test of SGS and Intertek, etc.

Welcome to visit our factory!