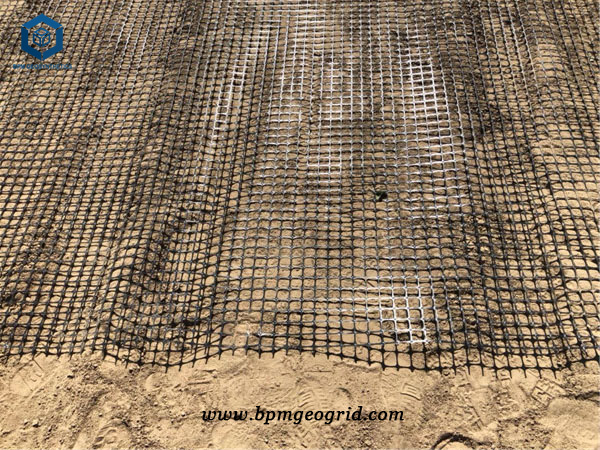

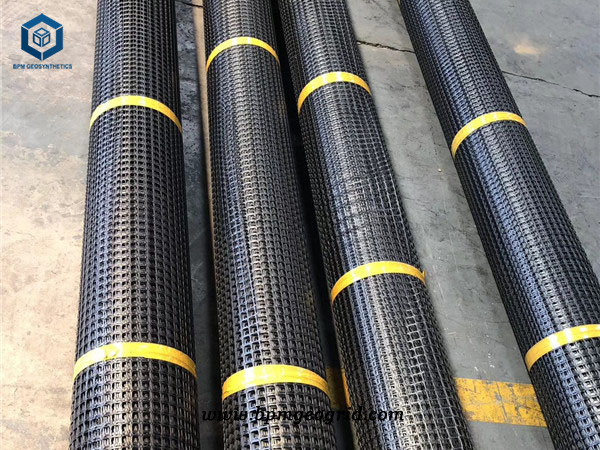

HDPE Geogrid, also known as high density Polypropylene geogrid, is manufactured from high density polypropylene material through the process of extruding, punching, heating and stretching.. HDPE Biaxial plastic geogrid is a kind of two-way geogrid. Compared with other geosynthetics, it has unique performance and efficacy.The properties of Biaxial Geogrids, designed with with their square apertures, high tensile strength and optimized geometry of nodes and ribs make them equal to any other similar material. The reinforcing action of Biaxial HDPE Geogrid lies mainly in confining soil and increasing its shearing resistance by a process of interlocking between the square ribs and the soil. The load dispersal effect from the interlocking mechanism is highly effective and can reduce sub-base thickness and construction cost. HDPE Biaxial Geogrids can be used with any kind of mechanical fill material. Two aperture size ranges are available for optimum matching with project fill. The HDPE material has great tensile strength in both longitudinal and transverse directions. This structure can also provide an ideal interlocking system for more effective force bearing and diffusion in the soil, which is suitable for large-area permanent bearing foundation.Biaxial HDPE geogrid has the following functions. The HDPE biaxial geogrid is suitable for various dams and roadbed reinforcement, slope protection, cave wall reinforcement, large airports, parking lots, wharf cargo yards and other permanent bearing foundation reinforcement.

The characteristics of the Biaxial plastic geogrid products:

- Increase the bearing capacity of the road (foundation) and prolong the service life of the road (foundation);

- It canPrevent the road (ground) from collapsing or cracking, Keep the ground beautiful and tidy;

- Convenient construction, saving time and effort, shortening the construction period and reducing maintenance costs.

The BPM team received an inquiry about biaxial geogrid from a Chilean customer.

The Chilean customer is a road contractor. A section of the outskirts of the capital Santiago has been cracked and slightly collapsed. The total length is 20,000m and the road width is 4m. After calculation by their engineers, a 30kn two-way PP plastic grille is required. After communicating with the customer, the BPM team understood the customer’s engineering plan and product requirements. The HDPE 30/30 geogrid was recommended and samples were sent to the customer. After receiving the samples, after professional testing, the customer was very satisfied with the quality of the HDPE geogrid, and then confirmed the order.

Specifications of HDPE Geogrid for Road Construction in Chile

- Tensile Strength– 30KN/30KN

- Each roll size – 3.95m*50m

- Total geogrid quantity – 26267.5m2

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.