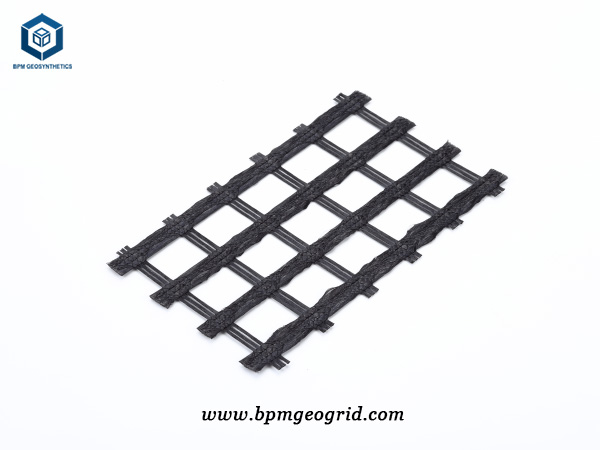

Geogrids functions and applications are the major concern for soil reinforcement below roads, under structures and behind retaining walls. Are the major geosynthetic materia, geogrid has unique properties, functions and applications geogrid compared with other geosynthetics. Geogrid is engineered with large openings or apertures which is made from polymers such as polypropylene, polyethylene or polyester.The geogrids are manufactured high strength reinforcement grid that comes in rolls of various sizes and strengths. The soil can strike through the apertures and the two materials interlock together to give composite behavior. The geogrid provides high strength and longevity to your wall to help prevent wall failure;resistant to biological degradation and naturally encountered chemicals, alkalis and acids. BPM innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc.

Geogrids Functions and Applications

The typical geogrids applications are as followed.

(1) Geogrids can improve the structural integrity of soils in roadways, walls and slopes by reinforcing and confining fill materials and distributing load forces. Geogrids are the answer for designers, developers and contractors facing the challenges posed by sloping ground and soft subgrades.

(2) Geogrids help soils stand at virtually any desired angle in grade separation applications. In retaining wall and slope applications, geogrids can be combined with a wide variety of facing elements to produce the desired aesthetics for any project.

(3) Geogrids provide support for the construction of access roads, highways, berms, dikes and structure applications that previously required the use of expensive over-excavating or piling methods on weak subgrades. Geogrids are also used in base reinforcement applications to reduce aggregate thickness requirements or extend roadway performance life.

The typical geogrids functions are as followed.

(1) Retaining Walls. The soil behind retaining walls can exert a tremendous amount of pressure on the blocks so it is very crucial to use a high quality geogrids in-between the blocks to help alleviate that pressure and keep the wall from falling over.

(2) Pavements, Embankments and Raft Foundations. In the engineering construction, geogrids offer high tensile stiffness, excellent resistance to damage during the construction process or environmental exposure.

(3) Dewatering Drainage Filtration. Composite geogrid is the ideal material to separate building materials with different physical properties such as soil and sand, sand and gravel, soil and concrete, to keep the two or more materials from losing or mixing, and maintain the overall structure and function of the material, such as the effective isolation between the roadbed and the foundation, the foundation and the embankment, the geomembrane and the sand draining layer.

(4) Slope Stability Systems. Geogrid is able to maintain the tensile reinforcement load and efficiently transfer that tensile load into the surrounding soil.

(5) Landfill and Environmental Barrier Systems. Geogrid is inert to biological degradation and resistant to naturally encountered chemicals, such as alkalis and acids.

(6) Surfacing Reinforcement. Geogrid is used to help retard reflective cracking in the asphaltic layers within flexible and composite pavements.

(7) Water Management Systems. Geogrids with a fabric backing to help with installation and provide a water retardation layer or waterproofing layer, and it also has moderate tensile strength for reinforcement.