Biaxial geogrid soil reinforcement is an essential geosynthetics material in the field of civil engineering and geotechnical applications. BPM geogrid is designed to reinforce and stabilize soil structures, providing enhanced load-bearing capacity and improved performance.

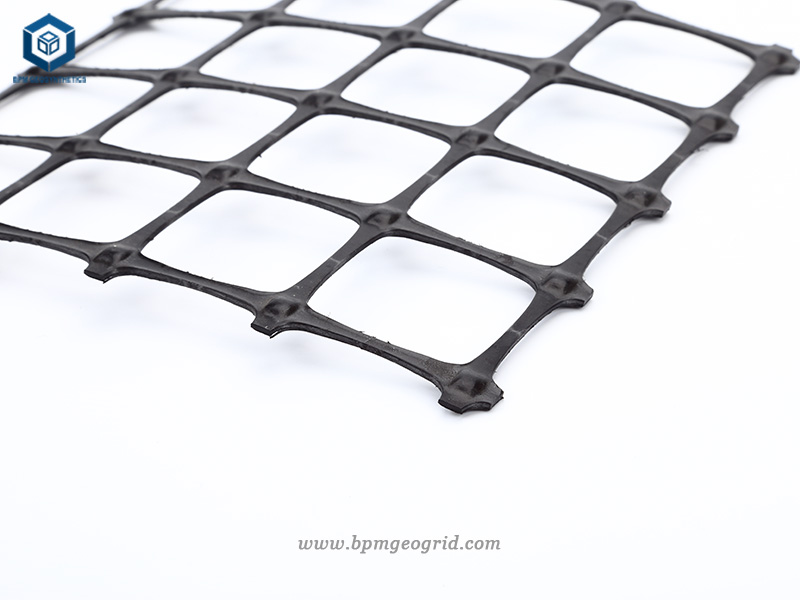

Biaxial geogrid soil reinforcement consists of a grid-like structure made from high-strength polymers such as polypropylene or polyester. The grid is formed by intersecting tensile ribs, creating apertures or openings. These apertures allow for the efficient interlocking with soil particles, resulting in improved load distribution and soil confinement. The key characteristics of biaxial geogrid is their high tensile strength in both the longitudinal (machine) and transverse (cross-machine) directions. This biaxial reinforcement enables them to effectively withstand heavy loads and resist deformation, making them ideal for soil stabilization and reinforcement applications.

Biaxial geogrids find extensive use in various geotechnical and civil engineering projects. One primary application is in the construction of roads, highways, and railways. By placing geogrids within the pavement structure, they improve the load-bearing capacity, reduce rutting, and prolong the service life of the pavement. Additionally, biaxial geogrids are widely used in the construction of retaining walls and embankments. They provide reinforcement to the soil, preventing slope failures and soil erosion. The geogrids help to stabilize the structure, distribute the lateral forces, and enhance the overall stability of the retaining wall or embankment. Furthermore, biaxial geogrids are employed in soil reinforcement applications for foundations, landfills, and coastal protection projects. They can effectively increase the stability and load-bearing capacity of these structures, mitigating the risks associated with settlement and soil movement.

Case Study

- Location : Ghana

- Product(s) : Biaxial Geogrid

- Application : Road construction

Issue

The original urban roads are mostly cement concrete pavement. With the increase of service life, road traffic and vehicle load, the damage of old cement pavement structure is becoming more and more serious. How to repair the old cement concrete pavement has become an urgent problem to be solved. The reconstruction of traditional slab pavement is not only time-consuming and laborious, but also has the opinions of many people. Asphalt pavement equipment has the advantages of good flatness, low noise and less dust. Paving asphalt overlay on old concrete pavement is an effective measure to improve the service performance of old concrete pavement, but the reflection crack of asphalt overlay is the main problem to be solved.

Solution

In view of this situation, BPM Geosynthetics proposed to lay biaxial geogrid soil reinforcement layer on the old cement concrete pavement, and then lay an asphalt concrete surface layer on it. The pavement paved by this method can prevent the reflection of base crack, reduce the rutting of pavement and prolong the service life of pavement. biaxial geogrid soil reinforcement has the characteristics of high tensile strength, low elongation, no creep, good compatibility with asphalt mixture, stable physical and chemical properties, high temperature resistance, strong locking and strong limit effect. Its main function is to transmit axial load uniformly. The stress of reflection crack changes from vertical to horizontal. At the same time, it can improve the overall tensile strength of asphalt mixture, effectively improve the stress distribution of pavement structure, and resist and delay the generation of reflection cracks caused by pavement base cracks in asphalt concrete pavement. Thus, the service life of the pavement is improved.

Benefits

Biaxial geogrid soil reinforcement is applicable to the reinforcement of various dikes, embankments and subgrade, slope protection, tunnel wall reinforcement, permanent bearing foundation reinforcement of large airports, parking lots, docks and freight yards, etc.

- Biaxial geogrid soil reinforcement is used to increase the bearing capacity of subgrade and prolong the service life of subgrade.

- Biaxial geogrid is used to prevent the collapse or crack of the road (ground) surface and keep the ground beautiful and tidy.

- Biaxial geogrid soil reinforcement is used for convenient construction, saving time and labor, shortening the construction period and reducing the maintenance cost.s

- Biaxial geogrid is used to prevent cracks in culverts.

- Biaxial geogrid is used to strengthen soil slope and prevent water and soil loss.

- Biaxial geogrid is used to reduce the thickness of cushion and save cost.

- Biaxial geogrid soil reinforcement is used to support the stability and greening environment of grass planting mesh pad on the slope.

Biaxial Geogrid Features

- Excellent mechanical properties and long-term stability.

- High tensile strength.

- High wear resistance.

- Anti-corrosion resistance.

- Balanced vertical and horizontal strength.

- Strong tearing resistance.

- Excellent soil surface adaptability, especially the tilted or curved surface.

- High resistance to dynamic impact load and vibration activity.

- Strong strengthening ability.

- Excellent resistance to differential settlement.

- Easy to install.

Construction method of Biaxial Geogrid:

- Construction site. Biaxial geogrid soil reinforcement is required to be compacted, flat and horizontal, and remove spikes and protrusions.

- Biaxial geogrid soil reinforcement laying. On the flat and compacted site, the main stress direction (longitudinal) of the grid installed and laid shall be perpendicular to the axis direction of the embankment. The biaxial geogrid soil reinforcement shall be laid flat without wrinkles and tensioned as much as possible. Fix with dowel pins and earth rock ballast. The main stress direction of the laid grid is the full length without joints. The connection between frames can be bound and overlapped manually, and the overlapping width shall not be less than 10cm. If the grating is set in more than two layers, the joints between layers shall be staggered. After large-area laying, its flatness shall be adjusted. After a layer of soil is filled and before rolling, the grid shall be tensioned manually or with machines and tools again, and the force shall be uniform, so that the grid is in a straight stress state in the soil.

- Selection of filler. The filler shall be selected according to the design requirements. It is proved by practice that it can be used as filling material except chalk soil and diatomite. However, gravelly soil and sandy soil have stable mechanical properties and are little affected by water content, so they should be preferred. The particle size of filler shall not be greater than 15cm, and pay attention to control the grading of filler to ensure the compaction weight.

- Paving and compaction of filler. When the grid is laid and positioned, it shall be filled and covered in time. The exposure time shall not exceed 48 hours. The flow operation method of laying and backfilling can also be adopted. First pave the filler at both ends, fix the grid, and then push it towards the middle. The rolling sequence is from both sides to the middle. During rolling, the roller shall not be in direct contact with the reinforcement, and the uncompacted reinforcement is generally not allowed to be driven by vehicles, to avoid the dislocation of the reinforcement. The compaction degree of each layer is 20-30cm. The degree of compaction must meet the design requirements, which is also the key to the success or failure of reinforced soil engineering.

5. Waterproof and drainage measures. In reinforced soil engineering, drainage treatment inside and outside the wall must be done well; Protect feet and prevent scouring; Filter and drainage measures shall be set in the soil. If necessary, geotextile and geogrid soil reinforcement shall be set. It is an excellent geosynthetic material used for Pavement Reinforcement, old road reinforcement, subgrade reinforcement and soft soil foundation. It has become an irreplaceable material in the application of asphalt pavement reflection crack treatment. The product is a semi-rigid product made of high-strength alkali free glass fiber through warp knitting process and surface coating treatment. It has high tensile strength, low elongation and high temperature resistance, low cold resistance, anti-aging and corrosion resistance. It is widely used in asphalt pavement, cement pavement and roadbed reinforcement, railway subgrade, embankment revetment, airport runway, sand prevention and other engineering projects.

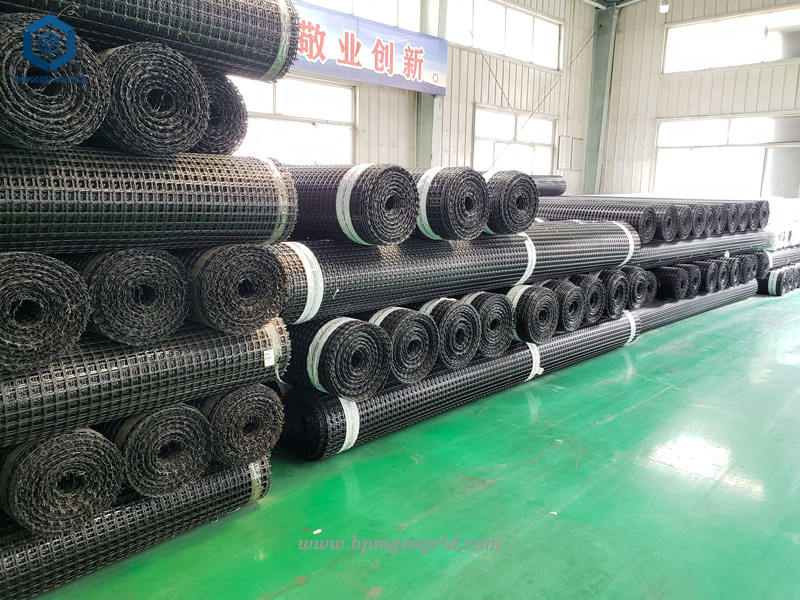

Specifications of Biaxial Geogrid Soil Reinforcement for Road Construction in Ghana

- Properties – 30/30 kN/m

- Specification – 3.95m×50m

- Total quantity – 85,320 square meters

- Delivery time – 15 days

About BPM Geosynthetics

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001, Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.