Biaxial geogrid installation includes biaxial construction methods and processes. Biaxial geogrid is one of the important geosynthetic products commonly made with polymer materials. Due to the abilities of strength in tension and heavy load distribution across large area, BPM biaxial geogrid is widely used to reinforce soils and other materials in construction applications such retaining walls, foundation soil and pavement construction, etc. Typical geogrid products can be divided into biaxial geogrid and uniaxial geogrid. BPM biaxial geogrid have the features of strong tension, higher bearing load capacity, easy construction, land optimization, soil erosion protection, lower maintenance cost, etc. Biaxial geogrid installation guidelines play important role to ensure the life spans and effects of geogrid reinforcement.

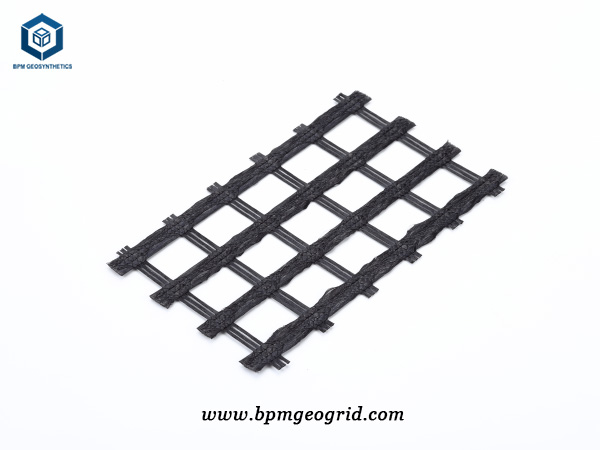

The biaxial geogrid is the geogrid that offers unique performance and efficacy compared to other geosynthetics. The biaxial geogrid is formed by stretching, forming, punching, and then longitudinally and transversely using a polymer. The material has great tensile strength in both the longitudinal and transverse directions. This structure also provides an ideal interlocking system for more efficient force bearing and diffusion in the soil, suitable for large-area permanent bearingcfoundation.

BPM biaxial geogrid are made of polypropylene (PP) through extrusion, punching and drawing. BPM biaxial geogrid with a rectangular cross-section of the rib. In the manufacturing process, the perforated PP plate is stretched biaxially. Owing to solid construction without any interconnecting junctions, biaxial geogrid is extremely durable and resistant to stretching. BPM biaxial geogrid interlock with aggregate particles creating an enhanced composite material with higher performance characteristics. The profile shape and thickness of the structural ribs contribute to superior confinement and stabilization of the reinforced layer. BPM biaxial geogrid can carry high tensile loads applied in both longitudinal and transverse directions with superior stiffness and junction strength for reinforcement applications, including pave or unpaved road construction, railway improvement and soft soil stabilization.

Biaxial Geogrid Features

1.Good solution for ground stabilization

BPM biaxial geogrid has very high modulus which makes the biaxial geogrid has extremely low elongation and creep performance. BPM biaxial geogrid has higher product integrity with uniform and stable open apertures to improve the interlocking between the rigid square ribs and soil. Additionally, BPM biaxial geogrid has higher junction strength and connection strength, which are also beneficial to performing the functions of confinement and reinforcement.

2.High quality and durability

The material of biaxial geogrid, polypropylene, has excellent resistance against chemicals including acid and alkali, which is normally contained in soils. The integral formation of biaxial geogrid strengthens its ability to resist installation damage. Through the quality assurance process certified with ISO 9001, BPM company are provided with high quality to all customers.

For decades, biaxial geogrid has been used widely for road construction in the world, and have shown their benefits in extending service life of road , increasing bearing capacity, and reducing base thickness and construction costs. The benefits of using BPM biaxial geogrid include:

- Increase bearing capacity of road structure to extend service life (or maintenance intervals)

- Strengthen road base layers to withstand risks such as over high or intense wheel loads, differential settlements and earthquakes, etc.

- Reduce base thickness to reduce costs

The biaxial geogrid has great tensile strength in both the longitudinal and transverse directions. This structure provides an ideal interlocking system for the more effective force bearing and diffusion in the soil, adapting to large area permanent, the foundation of the bearing is reinforced. BPM biaxial geogrid provides a simple, cost effective solution for soil reinforcement. Improve roadways, highways and other heavily trafficked areas with BPM biaxial geogrid.

Biaxial Geogrid Applications

BPM Biaxial geogrid can be used for building approach walls, retaining walls, bridge abutments, temporary walls (including staging platforms, traffic diversion, and pre-load walls) and vegetated Reinforced Steepened Slopes (RSS).

1.Reinforcement of road substructures

2.Construction of temporary and technological roads

3.Construction of forest roads

4.Construction of access roads to wind-farms

5.Construction of parking areas

6.Reinforcement of substructures of railway tracks

7.Reinforcement of embankments and dykes

8.Reinforcement of building foundations

9.Reinforcement of substructures under technical floors and mass storage areas

Biaxial Geogrid Installation Guidelines

Before biaxial geogrid installation, some necessary preparation should be carried out to ensure the efficient and effective biaxial geogrid installation. Firstly, the construction site is required to be compacted and leveled, and the spiked protrusions are removed.: On the flat and compacted site, the main force direction (longitudinal direction) of the installed biaxial geogrid should be perpendicular to the axis of the embankment. The laying should be smooth, without wrinkles, and tension as much as possible. It is fixed by inserting nails and earth-rock pressure. The main direction of the laying of the grille is preferably long and no joint. The connection between the web and the web can be manually tied and lapped, and the overlap width is not less than 10cm. If the biaxial georid is set to be more than two layers, the layers should be staggered. After laying a large area, the overall straightness should be adjusted. After filling a layer of soil, before the crushing, the grille should be tensioned again with manual or machine tools, and the force should be even, so that the grille is in a straight state under the soil.

Secondly, Fillers should be selected according to design requirements. Practice has proved that in addition to frozen soil, marsh soil, domestic garbage, chalk soil, semiautomatics earth can be used as filler. However, the mechanical properties of gravel soil and sand soil are stable and have little influence on water content, which should be preferred. The particle size of the filler should not exceed 15cm, and the filler gradation should be controlled to ensure the compaction weight. When the biaxial geogrid is laid and positioned, it should be filled in time, and the bare time should not exceed 48 hours. It can also be used as a running method for backfilling while laying. First spread the packing at both ends, fix the grille, and then push it toward the center. The order of rolling is first and then the middle and the back. When the roller is pressed, the pressure roller cannot directly contact the ribs. The uncompacted reinforced body generally does not allow the vehicle to travel on the top to avoid the misalignment of the ribs. The partial lamination is 20-30 cm. The degree of compaction must meet the design requirements, which is also the key to the success of reinforced soil engineering. Lastly, waterproof and drainage measures: In the reinforced soil project, it is necessary to do the drainage treatment inside and outside the wall; to protect the feet and prevent erosion; to set up filtration and drainage measures in the soil, if necessary, geotextiles should be installed and permeable Tube (or blind ditch). Drainage by means of dredging, can not be blocked, otherwise it will cause hidden dangers. So, the biaxial geogrid installation can be finished properly. Followed is the biaxial geogrid installation methods.

When used for roadbed and pavement, the biaxial geogrid excavates the bed, sets the sand cushion (the height difference is not more than 10cm), crushes it into a platform, and lays the grille. The longitudinal axis should be consistent with the main direction of force. Lap 15-20cm, horizontal 10cm, the lap joint is tied with plastic belt, and on the laying grille, the U-shaped nail is fixed to the ground every 1.5-2m, and the biaxial geogrid should be backfilled in time and laid. The biaxial geogrid layer is based on technical requirements.

The paving surface of the biaxial geogrid should be relatively flat. After the experience of the paving layer is accepted, in order to prevent the longitudinal skew phenomenon, firstly draw a white line or a hanging line according to the width of the paving layer, then the paving can be started, and then the iron is used. Nail fixing the end of the grille (8 nails per meter wide, uniform distance fixed), after fixing the end of the grille, use the paving machine to slowly pull the grille forward, artificially 10 meters long Tighten and straighten once, until a roll of grille is finished, then roll the next roll, operate the same as before, after rolling a roll, use the 6T-10T roller to roll from the starting point to the forward direction. ( If paved on the middle layer and leveling layer, it is advisable to use a steel roller road roller; if the grille is directly laid on the concrete pavement, it is advisable to use a rubber roller road roller.) Picking: the length of the coil is used as the laying section. Long, after the length of the section of the paving biaxial geogrid is covered, the paving quality is checked once, and then the next section is laid. When the next section is paved, the biaxial geogrid and grille can be overlapped by 10-15CM. And after fixing with iron nails or wooden wedges, continue to lay the second section in the forward direction, and so on, the operation requirements are the same as before.

The biaxial geogrid installation method can be as simple as we imagined. It can be done not only by the action of laying. When laying, there are still many problems that need our attention, and the work of the aftermath is indispensable. The paving surface of the biaxial geogrid should be relatively flat. After the paving layer has passed the inspection, in order to prevent the longitudinal tilting appearance, first draw the white line or the hanging line according to the width of the paving layer, then start paving, then insert The end of the nail fixing biaxial geogrid (eight nails per meter width, evenly spaced). When laying the biaxial geogrid, it should be straightened and tightly attached to the base surface, and the biaxial geogrid should be fixed to the foundation with a nail every 2-2.5m. The biaxial geogrid is bundled with plastic straps along the transverse joints. Pick-up: Take the length of the roll as the length of the paved section. Cover the length of the section where the grille should be laid. Then check the quality of the paving, and then lay the next section. The connection of the biaxial geogrid is selected by lap joint construction. In order to ensure its integrity, the lap length is not less than 20cm and not less than 3 holes, and the lap length should be tight. When a section of biaxial geogrid is laid, the 25-50Kg sand bag is fixed to the biaxial geogrid lap joint and the margin. In order to prevent the biaxial geogrid from being damaged, the foundation of the base layer should be flat, and it is forbidden to have solid protrusions such as gravel and stone. After the biaxial geogrid is laid, it is necessary to carry out the construction of the bagged sand on both sides in time. After the filling of the bagged sand on both sides is completed, the construction of the medium coarse sand cushion is carried out immediately. Avoid damage to the biaxial geogrid by tidal water.