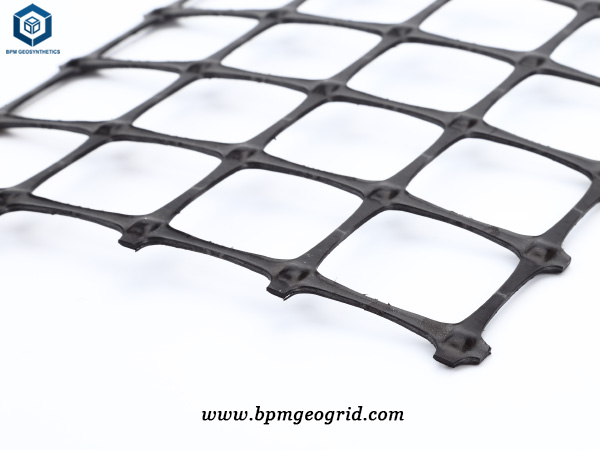

Biaxial geogrid fabric has high tension strength and excellent bearing capacity in both longitudinal and horizontal direction which can provide a interlock system for the soil, and the biaxial geogrid fabric is suitable for the improvement of roadbed with large area permanent load, such as mechanical ground stabilization, soft soil foundation treatment and other reinforced earth structures, reinforced foundations and working platforms. Plastic biaxial geogrid is often made from plastic materials which may be high-density polypropylene or high-density polyethylene (HDPE) resins through the processes of extruding, sheet forming, punching and stretching, etc. The biaxial geogrid fabric is the ideal geosynthetic material to enhance soil structure, prevent soil erosion, increase stability and loading capacity of foundation, prolong the project life for highway, railway, slope protecting projects and airfields, etc.

Asphalt concrete pavement is widely used in the construction of highways in various countries, but the effect of load stress will cause serious damage to the asphalt concrete pavement, thereby shortening the service life of the highway. Therefore, in order to improve the quality of the asphalt concrete pavement, measures need to be taken to improve its stability. For example, by increasing the application of the geogrid fabric, the quality of the asphalt concrete pavement can be effectively improved. and prevent road for rutting and cracking.

Role of PP Biaxial Geogrid Fabric in Asphalt Highway Construction

First, improve the high-temperature rut resistance of asphalt concrete pavements. Under the influence of many factors, it is easy to cause the high-temperature stability of the asphalt mixture to be reduced, thereby causing rutting-which will affect the driving comfort, and even in serious cases, there will be hidden dangers to traffic safety. The application of the biaxial geogrid fabric in the asphalt concrete pavement can improve the supporting capacity of the asphalt concrete pavement, thereby adding a layer of guarantee for traffic safety. In addition, the addition of a geogrid fabric to the asphalt mixture can enhance the bearing capacity of the asphalt concrete pavement, and the biaxial geogrid fabric serves as an independent anchor point to limit the displacement of the aggregate, so that the asphalt mixture interacts with the grid. It is of great significance to improve the stability of the mineral framework.

Second, delay cracks in asphalt concrete pavements. The tensile strength of the plastic and mesh i in the biaxial geogrid fabric is large. Adding these mixtures to the asphalt concrete structure layer can improve the strength of the pavement material and enhance its performance. When the geogrid is laid, the expansion angle of the crack can be increased to play a role in delaying the occurrence of cracks.

Third, reduce the thickness of the asphalt layer. When the geogrid is laid on the asphalt concrete pavement, the stress distribution of the pavement structure is changed, which can reduce the tensile stress of the asphalt concrete mixture under the influence of the geogrid fabric, thereby enhancing the fatigue resistance of the asphalt pavement and delaying the asphalt Pavement cracks appeared. The use of geogrids in the construction of asphalt concrete pavements can reduce the thickness of asphalt to 5cm to 10cm, which has an important role in reducing the amount of asphalt mixture.

BPM Korean customer purchased PP Biaxial Geogrid fabric from us in order to increase the strength of the asphalt concrete pavement and reduce the occurrence of diseases such as cracks and ruts.

The production material of the biaxial geogrid fabric used by the Korean customer for this project is Polypropylene. The tensile strength of the two-way geogrid fabric used is 50KN/50KN, and the change in modulus must be consistent with the tensile strength. Because the biaxial geogrid fabric has the function of reinforcement, so the biaxial geogrid fabric can be added to the asphalt concrete pavement, the geogrid can integrate the mixture in the mesh together, and the bridge can reduce the displacement of the asphalt concrete pavement. . Therefore, in the construction process of asphalt concrete pavement, choosing an appropriate geogrid has an important effect on improving the overall quality of the pavement.

Specifications of Biaxial Geogrid Fabric for Asphalt Highway Construction in South Korean

- Total geogrid fabric quantity – 62,000square meters

- Each roll size – 95m*50m

- Tensile Strength– 50KN/50KN

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geosynthetics products include geomembrane, geotextiles, geocell, geosynthetic clay liners (GCLs), drainage boards, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.