Biaxial geogrid solutions are best for applications such as foundations for roadbeds , railroad truck beds, permanent unpaved roads, airport runways, construction haul roads, working platforms on weak subgrades, and packing lots. BPM Biaxial geogrid is made of high molecular polymer after extruded and laminated and punched into regular mesh before longitudinal stretching, this process makes high molecule in direct line state in oblong oval net structure with uniform distribution and high node intensity, This structure has rather high tensile strength and stretch modulus, especially our products of this kind have superior world class tensile strength and stretch modulus with extensibility between 2% and 5%, the soil offers ideal force carrying and diffusing chain system, It has large tensile strength (>150Mpa), and is suitable for different kinds of soil.

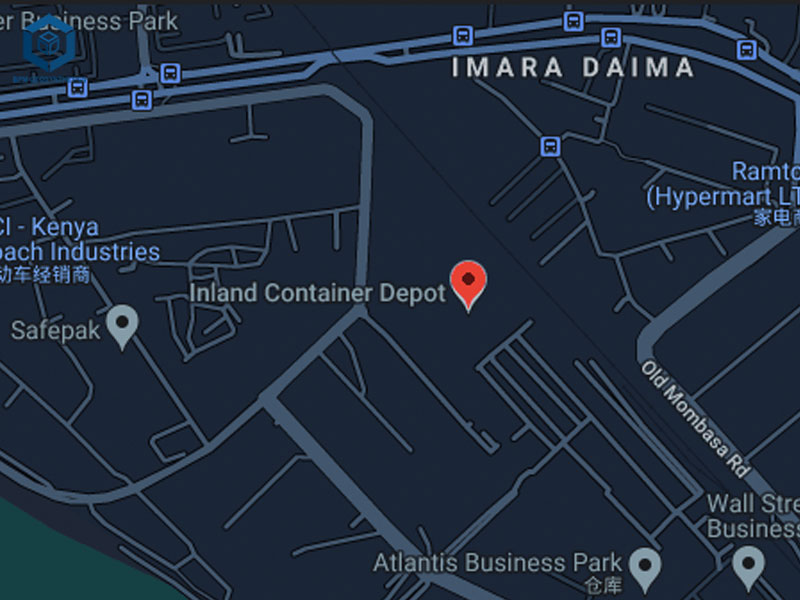

BPM Biaxial Geogrid Solutions for Inland Container Deport Project in Nairobi

BPM biaxial geogrid is a geosynthetic compound made out of polypropylene polymers and are primarily used to reinforce and stabilize soils. They are made through a series of procedures including crossway stretching, lengthways stretching and extruding. This production process ensures that all the geogrids have high tension resistance along with a high tensile strength, which therefore increases the overall bearing force that the geogrids are capable of.

It is important to also understand that there are three different types of geogrids available on the market, such as uniaxial geogrid, biaxial geogrid and triaxial geogrid. In our case we are focusing on the Biaxial Geogrid which is designed to ensure that the subgrade is strong in two directions, both length and width. This is why these types of geogrids have been used for projects like pavement and road stabilization for over thirty years.

If the soil in the area where you will be adding a dense load (such as slabs, railway sleepers, trucks or lorries) is too soft, the pressure will force the soil to warp. A Geogrid will help to secure the soil through compacting the aggregate which furthermore enhances the bearing capacity of the underlying ground. Unlike when the load is introduced to the soil alone, the geogrid forces the heavy load’s pressure to be spread over the entire surface area of the grid, due to the subgrade having strength in both directions.

This essentially means once the biaxial geogrid solutions are set out and the heavy load is put in place the soil beneath the grid compacts and the subgrade’s strength is further enhanced. This means that it is very cost effective by saving both labor and maintenance expenses.

Inland Container Depot Nairobi, owned and operated by Kenya Ports Authority and linked by Rail with Mombasa port provides shippers with dry port facilities in the commercial heart of the country and it was established in 2016. The spacious yard of 29 hectares located in Industrial area off Mombasa Road on ICD Road can accommodate a throughput of over 180,000 TEUS per annum making it ideal for shippers of both Exports and Imports and also Empty containers. In order to bring port services closer to its customers and reduce port congestion, KPA has constructed inland container depots at Nairobi, Kisumu and Eldoret. These depots are linked to the Mombasa Port container terminal by a rail-trainer service. Imports are delivered directly from Mombasa to the depots on a Through Bill of Lading, while exports can also be consolidated at the ICD and railed to the Port for shipping.

The port construction includes wharves, port roads, container yards, revetment engineering, and some comprehensive engineering construction such as breakwaters. Therefore, the port construction comprehensively involves the use of geosynthetic solutions. The soil in the surface layer in the port region is mostly muck and muck clayed soil, which is classified as soft soil with high water containment, high void ratio, lower shear strength and lower permeability. The 4~15 meters underground soft soil layer is mucky clay and mucky silty layer of marine deposit. The physical and mechanical indices of this soft soil layer are slightly better, but the deeper silt and limonitic layer has better physical and mechanical properties. So BPM geosynthetic solutions such as geotextile, geomembrane, geogrid are the ideal application to enforce, strength and stabilize the weak and soft soil foundations. geogrid are often use for foundation reinforcement.

How to lay Biaxial Geogrid?

Before placing any geogrid down you must first prepare the subgrade. The subgrade must be leveled out with compliance to any standards in order to ensure the whole job can be performed correctly and efficiently, and within any guidelines set out by construction standards specific to your project. It is also advised that heavy duty hand protection is worn when handling biaxial geogrid.

The geogrid can firstly be placed parallel to the central line of where your project is taking place or in the crossway’s direction. If you are needing to use a geotextile membrane for reasons such as your site experiencing ‘pumping’, then this should be laid down before you place the geogrid.

There must be an overlap between the adjacent rolls. The size of this overlap will depend on the grading and the thickness of the fill and type of subgrade. As standard a minimum overlap tends to be 300mm and a maximum of 600mm. Commercial projects may vary with contracted agreements.

While performing the overlap stage it is a necessity to ensure the overlaps are secured during the filling stage. This can be achieved by putting small amounts of fill to keep the overlaps in place before the actual filling process begins. A good aggregate fill is suitable for placement over the geogrid.

During the fill process it should be placed in small layers and not directly tipped onto the geogrid. Care should be taken when handling the geogrids, to minimise the risk of damage. There are standards associated with every different project and the compaction must be carried out in accordance with the rules set out.

Specification of Biaxial Geogrid Solutions for Inland Container Deport Project in Nairobi

- Total Biaxial Geogrid : 99540sqmB

- Each roll : 3.95m*100m and 178kg/rolls

- Container : 40hq * 2 container

BPM Biaxial Geogrid make reinforcement treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce un-even settlement, used in highway, railway, port, airport and municipal.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.