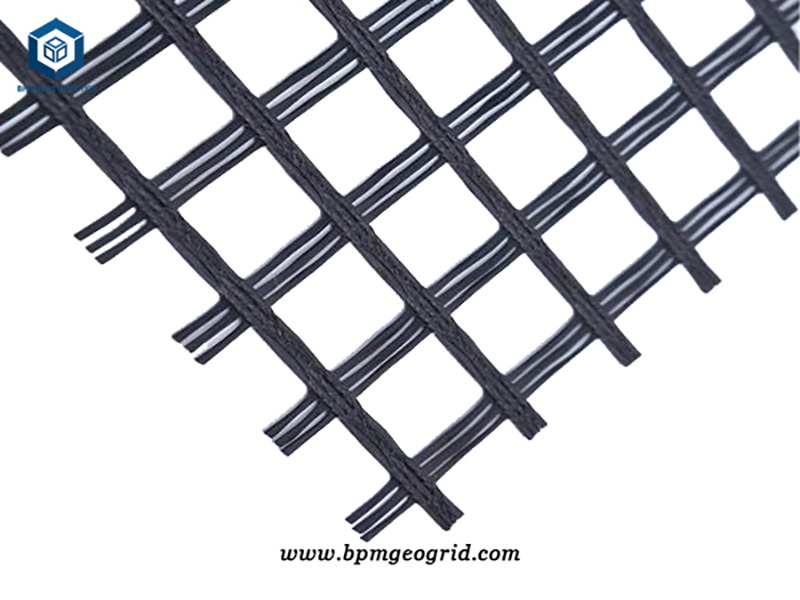

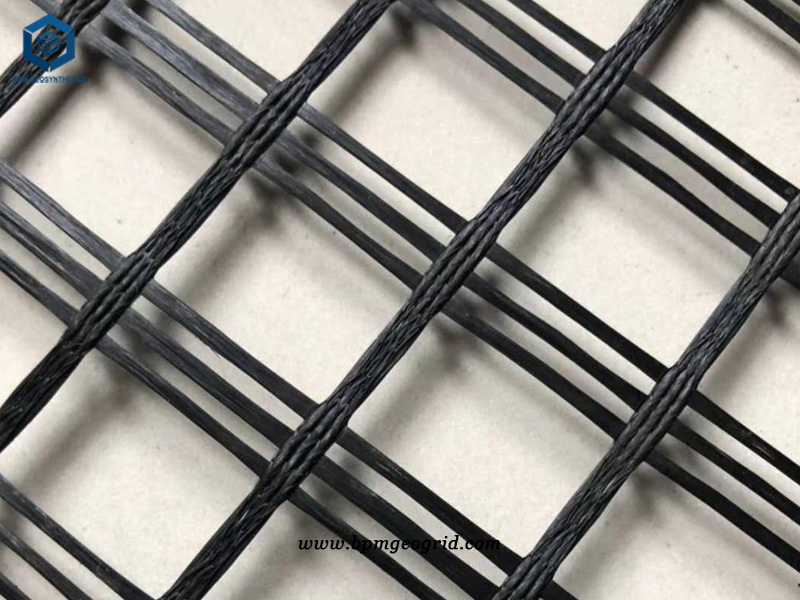

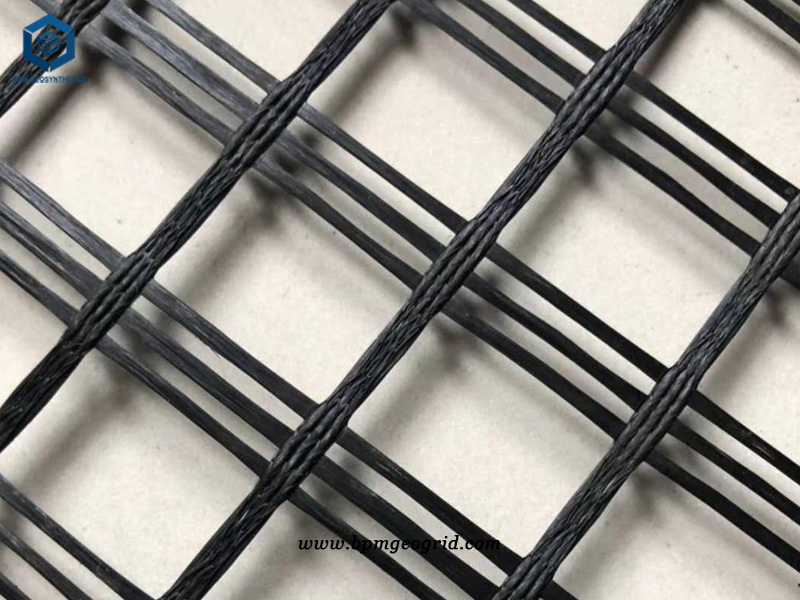

Fiberglass geogrid mesh is an excellent geosynthetic material used for pavement reinforcement, old road reinforcement, and reinforcement of roadbeds and soft soil foundations. The high-strength alkali-free fiber glass is a semi-rigid product made by using internationally advanced warp knitting technology to make a net-like substrate and surface coating treatment. It has high tensile strength and low elongation in both warp and weft directions, and has excellent properties such as high temperature resistance, low cold resistance, aging resistance, and corrosion resistance. The fiberglass geogrid mesh is widely used in asphalt pavement, cement pavement and roadbed reinforcement and railway Engineering projects such as roadbed, dam slope protection, airport runway, and sand prevention and control.

The fiberglass geogrid mesh is a mesh structure material made of fiberglass and a certain weaving process. In order to protect the fiberglass and improve the overall performance, it is a geocomposite material made by a special coating process.

The fiberglass geogrid mesh has the characteristics of high tensile strength in vertical and horizontal directions, low elongation, high elastic modulus, and excellent high and low temperature resistance. After surface coating treatment, it has excellent alkali resistance and aging resistance. Performance, widely used in the reinforcement of asphalt pavements, cement concrete pavements and roadbeds; applicable to both hard pavements and flexible pavements.

Compared with traditional pavements, it can reduce cost, prolong life and prevent road reflection cracks. Fiberglass geogrid can also be used for the reinforcement of soft soils such as railways, airports, water conservancy, dams, etc., and the reinforcement of roadbeds.

The main components of glass fiber are: silicon oxide, an inorganic material, its physical and chemical properties are extremely stable, and have high strength, high modulus, high wear resistance and excellent cold resistance, no long-term creep; thermal stability Good performance; the net structure enables the aggregate to be locked and restricted; it improves the load-bearing capacity of the asphalt mixture. Because the surface is coated with special modified asphalt, it has double compound performance, which greatly improves the abrasion resistance and shearing ability of the geogrid.

Sometimes combined with self-adhesive pressure sensitive adhesive and surface asphalt impregnation treatment, the fiberglass geogrid mesh and the asphalt pavement are closely integrated into one. As the interlocking force of soil and rock materials in the geogrid increases, the friction coefficient between them increases significantly (up to 08-10). The pull-out resistance of the geogrid buried in the soil is due to the interlocking force between the grid and the soil. The frictional bite force is stronger and significantly increased, so it is a good reinforced material. At the same time, the geogrid is a kind of plastic flat mesh with light weight and certain flexibility, which is easy to cut and connect on site, and can also be overlapped and overlapped. The construction is simple and does not require special construction machinery and professional technicians.

Case Analysis

- Construction site – Yunnan Province, China

- Products used – glass fiber geogrid with a specification of 125KN/m

- Application – Roadbed paving for rational construction

- The area of the geogrid used in construction: 60000 square meters

- The size of each roll of geogrid is 4m*50m

ISSUE

The project is located in Lijiang City, Yunnan Province, China. There is a road in disrepair in a small town below Lijiang City. Although the road is dilapidated, this road is the only way for the population in the area to travel daily. After many negotiations between residents and the construction company, a reasonable plan was made. The road started to repair works.

Renovating and repairing roads is a thing that benefits the people, and roads that have fallen into disrepair have seriously affected the travel of residents and the development of the local economy. Yunnan Province is located at southwestern border of China. The local economy lags other provinces in China. Therefore, it is imperative to build roads to promote local economic development.

Smooth roads are convenient for residents to travel. If the rural roads and muddy dirt roads in the past are expanded and hardened, the life and travel of rural people will be much more convenient. It shortens the travel time from rural to urban areas, and facilitates the travel of farmers’ friends.

At the same time, the transportation of agricultural products is convenient. In the past, it was really not easy for farmers’ friends to sell their agricultural products in cities and towns. They needed farmers to carry them on their shoulders, and they didn’t take much. It also benefits the development of local tourism. When roads are blocked, some tourist attractions are inconvenient roads, and it is difficult for people in the city to come and play.

Convenient transportation is conducive to the input and output of material and personnel between the local and the outside world, expand exchanges, gather local popularity, increase city reputation, population growth, and accelerate the process of local urbanization. Only when various industrial sectors have the possibility of further development and expansion of the city Radiation range.

Solution

In the early stages of preparing for road construction, the local government personnel in charge of the project wanted to find a reliable and long-life product. Most of the original urban roads are cement concrete pavements. As the service life, road traffic and vehicle load increase, the damage to the old cement pavement structure is getting more and more serious. How to repair the old cement concrete pavement has become an urgent problem to be solved. Renovating the traditional slab pavement is not only time-consuming and laborious, but also has many opinions. Asphalt pavement equipment has the advantages of good flatness, low noise, and less dust. Laying an asphalt overlay on the old concrete pavement is an effective measure to improve the performance of the old concrete pavement, but the reflective cracking of the asphalt overlay is the main problem that needs to be solved.

The reflective crack itself has little effect on the performance of the covering layer, but the negative influence of environmental factors (rain, snow, oxidation, dust) often causes the crack to expand rapidly and shorten the service life of the covering layer. In order to effectively slow down the reflection speed of cracks in the old cement concrete pavement or reduce the thickness of the asphalt overlay, researchers at home and abroad have conducted a large number of experiments, which have accumulated successful experience and learned many failed lessons. To prevent reflection cracks, the method of thickening the asphalt overlay is adopted abroad. However, simply relying on increasing the thickness of the pavement has its disadvantages: on the one hand, the increase in the thickness of the overlay is limited by the street elevation.

Moreover, the substantial increase in the thickness of the overlay will increase the cost of the road surface. In addition, the creep of summer asphalt mixture under high temperature can easily lead to rutting, thus losing the advantages of the solid foundation and thin surface produced by the old cement concrete slab as the base layer. Therefore, the method of thickening the asphalt overlay is not advisable. In response to this situation, on the basis of consulting a large amount of data, theoretical analysis and demonstration, it was decided to pave the glass fiber grille reinforcement layer on the old cement concrete pavement, and then pave the asphalt concrete surface layer on it. The pavement laid by this method can prevent the reflection of cracks in the base layer, reduce the rutting of the pavement, and prolong the service life of the pavement. The glass fiber grid has the characteristics of high tensile strength, low elongation, no creep, good compatibility with asphalt mixture, stable physical and chemical properties, high temperature resistance, strong locking, and strong ultimate effect. Its main function is to evenly transmit the axial load. The stress of reflection cracks changes from vertical to horizontal. The use of glass fiber grids can increase the overall tensile strength of the asphalt mixture, effectively improve the stress distribution of the pavement structure, resist and delay the generation of reflective cracks in the asphalt concrete pavement caused by the pavement base cracks. Thereby improving the service life of the road surface.

After browsing the related products on Alibaba, the project engineer sent us an inquiry. The personnel of our company have a detailed understanding of the customer’s needs and read the construction plan provided by the customer. Therefore, BPM recommended a 125KN/m fiberglass geogrid mesh products to meet the requirements of this project and consulting engineers. We sent them fiberglass geogrid mesh samples, company certificates, product inspection reports and other information. After receiving the samples, the customers are very satisfied with our products.

Main Application of Fiberglass Geogrid Mesh

- Reinforce the old asphalt concrete pavement to strengthen the asphalt surface to prevent and control diseases.

- The cement concrete pavement is converted into a composite pavement to suppress reflection cracks caused by plate shrinkage.

- Road extension and renovation project to prevent cracks caused by new and old junctions and uneven settlement.

- Reinforcement treatment of soft soil foundation is conducive to water seepage and consolidation of soft soil, effectively inhibits settlement, uniform stress distribution, and enhances the overall strength of the roadbed.

- The semi-rigid base layer of the newly built road produces shrinkage cracks, and reinforcement is strengthened to prevent pavement cracks caused by reflection of foundation cracks.

- Fiberglass geogrids have developed rapidly in recent times and are widely used in asphalt pavements, especially in asphalt overlays to slow reflection cracks. In some developed countries, such as Germany, the United States, Canada, Australia and Japan, glass fiber grille has been used for more than ten years, and the fiberglass geogrid mesh is widely used in high-grade highways, municipal roads and airport pavements and other demanding fields.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.