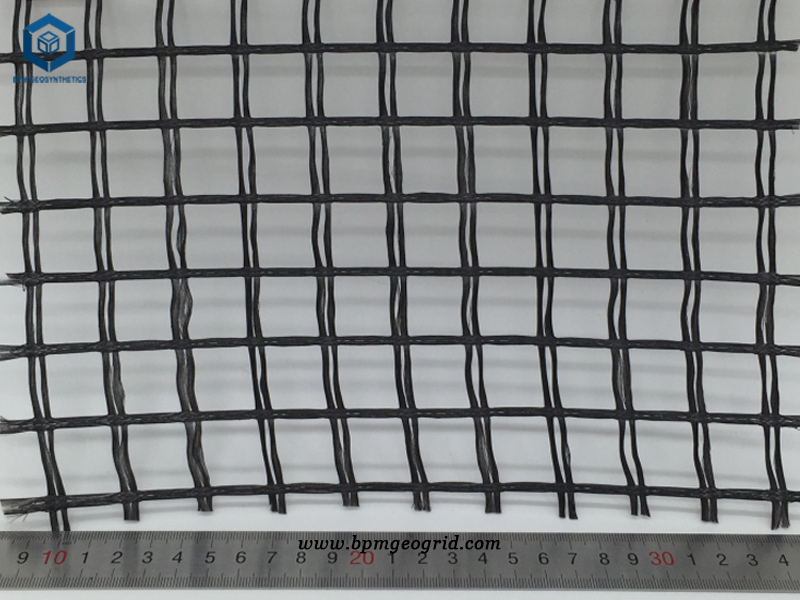

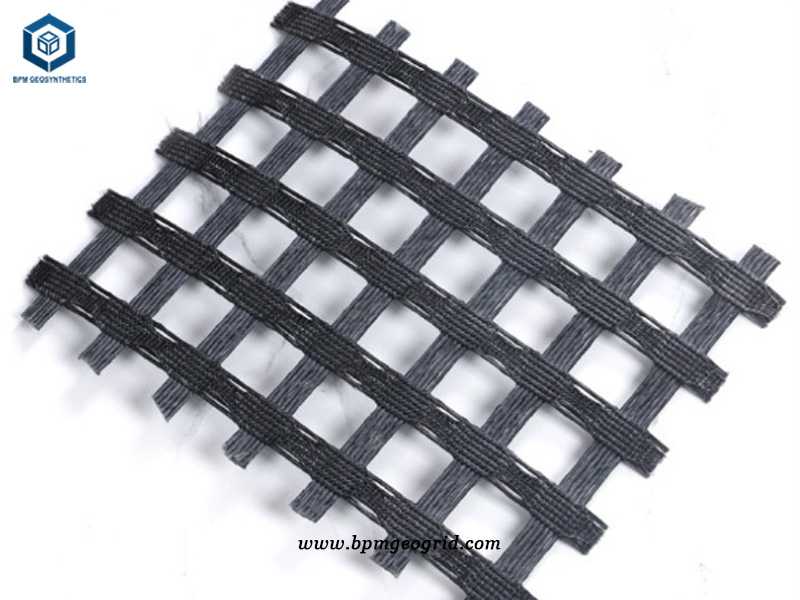

Warp knitting polyester extruded geogrid is engineered to be mechanically and chemically stable, in both harsh construction installation phase and in aggressive soil environments. It is the new high quality base geotechnical material for roadbed reinforcement applications. The warp knitted polyester extruded geogrid has the characteristics of high tension strength, low elongation ratio, excellent erosion resistant, aging-resistant, high occlusive force with soil or gravel.

CASE STUDY

- Location : Cuba

- Product: Warp Knitting Polyester extruded Geogrid 30-30

- Application : Road Construction

Issue

The customer said that the Cuban highway design has high requirements for subgrade strength and stability. When the vehicles across the road, it is necessary to overcome the crushing pressure of heavy load on subgrade. Therefore, it is necessary to select a grating with high strength, strong service life, corrosion resistance and stable strength level in the subgrade.

Solution

After discussion, BPM team recommended uniaxial plastic geogrid and warp knitted polyester extruded geogrid to customer. And the customer sent us the specification, we provided similar products the polyester geogrid 30/30Kn. The reason is that the high strength synthetic fiber is used as the raw material and the warp knitting oriented structure is adopted. The warp and latitude directions in the fabric are free from bending state. The intersection is bound with high-strength fiber filament to form a strong joint point and give full play to its mechanical properties. And this warp knitted polyester extruded geogrid might be cost-effective for the project. Meanwhile, we sent him the warp knitted polyester extruded geogrid samples. After communication and negotiation, finally, he confirmed the quality of our polyester geogrid products, then he signed order contract with us.

- Specifications – 30/30Kn

- Specification – 5.2m×100m

- Total quantity – 48,360square meters

- Delivery time – 15 days

Benefits

BPM Warp Knitting polyester extruded geogrid is engineered to be mechanically and chemically stable and biologically unaffected by soil micro-organisms. It is used for both harsh construction installation phase and in soil reinforcement application where strength develops uni-axially which can provide further chemical, mechanical and ultraviolet protection.

Application of warp knitted polyester geogrid.

- Soft soil reinforcement,isolation different earth materials in highway and railway.

- Slopestrengthening and stabilization.

- All kinds of ground strengthen.

- Strengthen the bridge surface.

Key points for warp knitting polyester extruded geogrid construction process.

- Construction site: it is required to be compacted and leveled, in horizontal shape, and sharp protuberances shall be removed.

- Grid laying: on the flat and compacted site, the main stress direction (longitudinal) of the grid installed and laid shall be perpendicular to the axis direction of the embankment, and the laying shall be smooth, without wrinkles, and as tight as possible. Fixed by inserting nails and earth rock weight, the main stress direction of the laid grid should be no joint in the whole length, and the connection between sheets can be manually bound and lapped, and the lap width should not be less than 10cm. If the grating is set in more than two layers, the seam between layers should be staggered. After large area laying, its flatness shall be adjusted as a whole. After a layer of soil is filled, before rolling, it shall be compacted again. Manual or machine should be used to tension the grid, and the force should be even, so that the grid is in a straight stress state in the soil.

- Selection of fillers: the fillers shall be selected according to the design requirements. Practice has proved that except frozen soil, swamp soil, domestic waste, chalk soil and diatomite, they can be used as fillers. However, gravel soil and sand soil have stable mechanical properties and little influence by water content, so they should be preferred. The particle size of the filler shall not be greater than 15cm, and the gradation of the filler shall be controlled to ensure the compaction weight.

- Paving and compaction of filling materials: when the grid is laid and positioned, it shall be filled and covered in time, and the exposed time shall not exceed 48 hours. The flow process method of laying and backfilling can also be adopted. First pave the filler at both ends, fix the grille, and then push it towards the middle. The rolling sequence is from both sides to the middle. When rolling, the roller can’t directly contact with the reinforcement, and vehicles are generally not allowed to drive on the uncompacted reinforcement to avoid dislocation of reinforcement. The layered compaction is 20-30cm. The degree of compaction must meet the design requirements, which is also the key to the success of reinforced soil engineering.

- Waterproof and drainage measures: in reinforced soil engineering, the drainage treatment inside and outside the wall must be done well; To do a good job of foot protection, anti erosion; filter and drainage measures shall be set in the soil, and geotextile and permeable pipe (or blind ditch) shall be set when necessary. Take the way of dredging drainage, can not be blocked, otherwise hidden.

After the geogrid is paved, the upper layer filler is laid manually, and the rolling is completed in time to avoid long-term exposure to the sun. Then, the material is transported, leveled and rolled mechanically. The mechanical paving and rolling are pushed from both sides to the middle, and the rolling is carried out from both sides to the middle, and the compactness is maintained to meet the specification requirements. All construction vehicles and construction machinery shall not be driven or parked on the paved geogrid. The quality of geogrid shall be checked at any time during construction. If any damage is found, such as breakage, puncturing and tearing, it shall be repaired according to the degree or replace.

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.