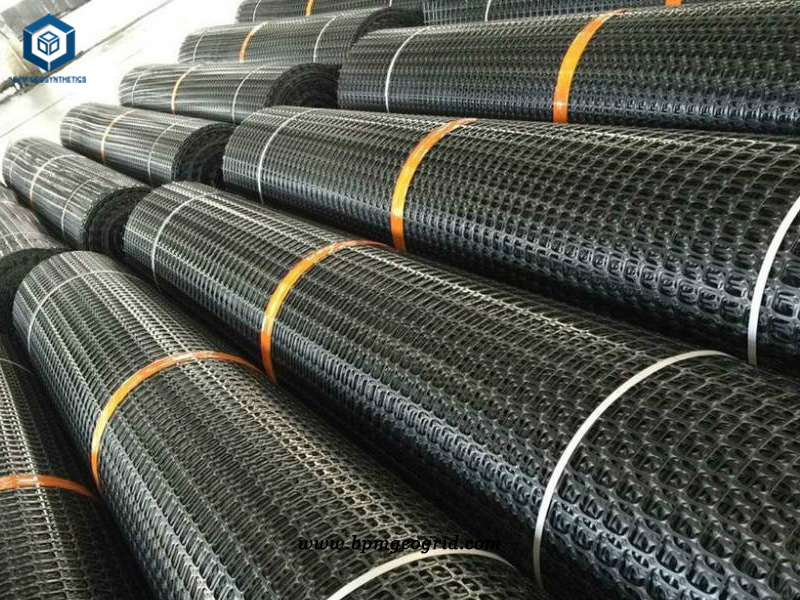

Polyester geogrid for gravel roads construction is the ideal and cost effective solution. The polyester geogrid is also known as plastic geogrid which is warp knitted by high tenacity polymer yarns as per desired mesh sizes and strength. As the widely used plastic geogrid, the polyester geogrids are often categorized as uniaxial geogrid and biaxial geogrid. The polyester geogrid for gravel roads is often has the following characteristics such as high strength, high tenacity polyester geogrids in a full range of tensile strengths from 20KN/M to 1000KN/m (Biaxial type), 40-25KN/m to 800-50KN/m at warp and welf directions (Uniaxial type). Polyester Geogrids are warp knitted and then coated with a PVC or SBR coating to provide dimensional stability.

Case Study

- Location: Tanzania

- Products: Polyester Geogrids

- Application: Road Construction

- Project:Upgrading of Dodoma-Babati Road to Bitumen Standard: Lot 1: Dodoma – Mayamaya Section (43.65 kms).

Issue

The Tanzania government planned a series of major road construction projects to greatly improve the transportation infrastructure. Building the nation’s roads, ports, railways and airport infrastructure was critical for the country to improve its internal and external trade and commercial activities. Moreover, the sector’s further development goes hand-in-glove with improvements in the energy sector as Tanzania strives to become a middle-income country. Tanzania’s client called BPM to inquiry polyester geogrid for gravel roads with specification and some pictures onsite. By checking specification and pictures onsite,BPM suggested 200-40 KN/m with relative technical data and installation guides for project onsite. As the professional geosynthetics and geogrid manufacturer, BPM provides the turn key solution for civil engineering construction projects.

Solutions

Site Preparation:

- Debris, stumps and other large plant growth should be removed from the site and a clean leveled surface should be formed.

- Care should be taken to avoid disturbing any surface crust overlying softer soil. In these cases, the geogrid should be placed directly on the unprepared subgrade.

- The fill material selected should generally be the graded material.

- It is best to have the graded filter analysis done by the geotechnical engineer.

Installation Details:

* Note: For safety reasons it is recommended that workers wear gloves and safety glasses while handling geogrid for gravel roads.

- Place geogrid in position and manually roll it out over the subgrade.

- Overlap the adjacent geogrid rolls in accordance with Table 1: Recommended Overlaps, below.

- Adjacent rolls should simply be overlapped and do not need to be tied together.

- Geogrid corners may be held down with shovelfuls of fill, sandbags etc.

| Soil Type | CBR(%) | Overlap(mm) |

|---|---|---|

| Firm | >3 | 400 |

| Soft Ground | 1-3 | 500 |

| Very Soft Ground | 1< | 600 |

Dumping, Spreading Fill & Compaction of Polyester Geogrid for Gravel Roads

- Do not operate equipment directly on the geogrid over soft ground.

- Thin fill lifts over soft subgrades may not be sufficient to support equipment. An initial lift of no less than 150 mm is required.

- For very soft conditions, the required fill thickness is a function of subgrade strength and construction procedure; usually it will be significantly greater than 150mm.

- Over relatively competent subgrades (CBR >2), fill may be dumped over

Ground that bears its weight and then pushed out over the geogrid.

- Work from Gstronger to weaker subgrade areas.

- The dozer blade should be gradually raised as the fill is pushed out over the biaxial geogrid. This will cause much of the fill to roll out onto the geogrid and will reduce stress on the subgrade.

- Back dump subsequent loads onto the leveled fill and advance forward over the fill by spreading with a dozer, and proceed in this cascaded fashion.

- Be aware of the directions of the geogrid overlap. Do not work against the pattern.

- If the wrinkles or waves develop in the geogrid, they will usually roll forward with the fill and out at the end of the geogrid roll.

- The fill material over the geogrid should be well compacted to a minimum 95% Proctor.

- Standard compaction methods can be used.

- If the soils are very soft, static rather than vibratory compaction should be used. Static Compaction is normally accomplished with a light roller and moisture. Water spray is especially efficient with sand fill.

Benefits

- The warp-knitted directional structure is adopted, the warp and weft yarns in the fabric are not bent with each other, and the intersections are bound with high-strength fiber filaments to form a firm joint point and give full play to its mechanical properties

- High-strength polyester fiber warp-knitted geogrid has high tensile strength, small extension force, high tear strength, and small vertical and horizontal strength differences.

- Ultraviolet aging resistance, abrasion resistance, corrosion resistance, light weight, strong interlocking force with soil or gravel, it has a significant effect on enhancing the shear resistance and reinforcement of the soil and improving the integrity and load capacity of the soil. High tensile strength, high tearing strength, and strong bonding force with soil gravel.

- It has the characteristics of high tensile strength, low elongation, corrosion resistance, aging resistance, strong base material occlusivity, light weight, and strong drainage capacity. The warp-knitted polyester geogrid is used to strengthen the soft soil roadbed of roads, railways, municipal roads, etc., which can effectively improve the strength of the roadbed and delay the reflection cracks of the road surface. The reinforcement and isolation of embankments and river embankments in warp-knitted geogrid water conservancy projects strengthens the foundation of soft soil foundations, enhances their protection capabilities, and improves the bearing capacity and stability of the foundation.

- The warp-knitted polyester geogrid is used to reinforce the side slope of the embankment, reinforce the retaining wall, enhance the overall strength, and reinforce the soft soil foundations such as highways, railways, and water conservancy. The warp-knitted polyester geogrid is used for the protection of railway and highway slag. Due to the vibration and wind of the train, the loss of road slag is caused. The earth grid is used to wrap the slag to prevent the loss of slag and improve the stability of the roadbed.

Summary

Polyester geogrids with PVC coating is a new kind of favorable earthwork base material to strength the road surface and roadbed, which composed of high strength polyester yarns coated with an inorganic sizing agent. The applications are reinforcement of Retaining wall, Slope, Ground base etc. with high tensile strength, low elongation, tear-resistant, anticorrosive and good anti-aging and alkali-resistance.

Specifications of Polyester Geogrid for Gravel Roads Construction Project in Tanzania

- Total geotextile quantity –2 2,000 squares meters

- PET Geogrid specification – 200-40 kN/m

- Each roll size is 5m*50m

About BPM

BPM manufactures and supplies many types of effective and state of the art geogrid, geomembrane, geotextile, and geosynthetics to over 36 countries. Our main innovative, high quality geogrid products include plastic biaxial geogrid, fiberglass geogrid, plastic uniaxial geogrid, warp knitting polyester geogrid, and steel plastic georgic mesh, etc. BPM brand brand high quality geosynthetic products had been certificated by the ISO9001, ISO14001,OHSAS18001 Soncap, SASO and BV, SGS and Intertek, etc.

If you have any questions or inquiries, please fill in and submit the form to contact us.